Polypropylene compound 332C

Polypropylene compound 332C is a polymer material that consists of polypropylene and other additives. Due to its special characteristics, this material is used in various industries such as packaging, automotive and electronics industries. In this article, the properties, uses, advantages and disadvantages of polypropylene compounds will be investigated.

Providing quality products to consumers has always been our priority, so to have a higher level of quality and service in products for production, contact Pedean Polymer.

Properties of 332C polypropylene compound

Polypropylene compound has unique properties that distinguish it from other polymer materials. This material has high resistance to heat, impact and shock and also has good electrical properties. Another important feature of polypropylene compound 332C is high resistance to chemicals, which makes this material suitable for use in industrial and chemical environments. Also, this compound has very good mechanical properties that make it widely used in the production of industrial parts.

Due to the above characteristics, 332C polypropylene compound can be used in the production of all kinds of car parts, household appliances, electrical and electronic appliances, sports equipment, etc. Also, this material is also known as a sustainable and environmentally friendly material due to its ability to be recycled and reused. As a result, polypropylene compound C332, with its unique features and wide application, is one of the most popular polymer materials in industries. It is different.

Applications of polypropylene compound in different industries

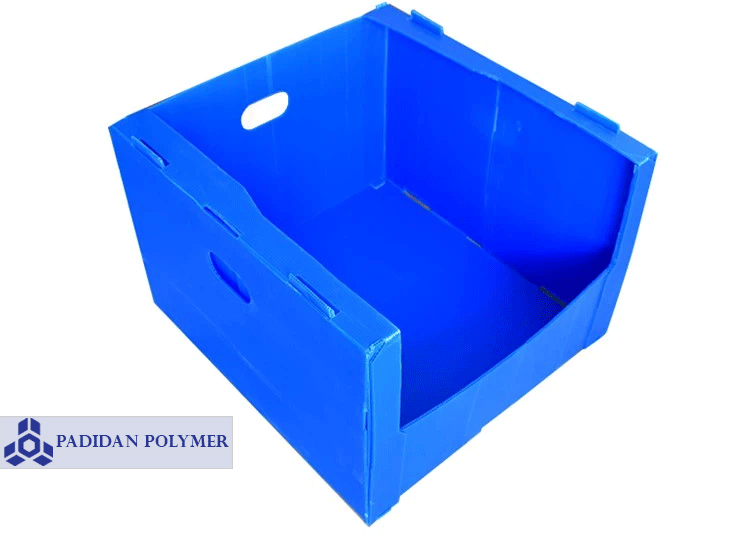

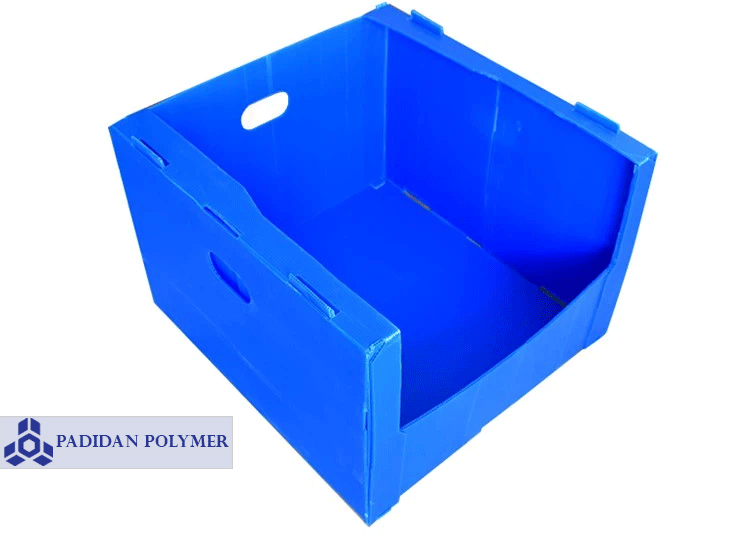

Due to the superior properties of the 332C polypropylene compound, this material is used in various industries such as packaging industries to produce bags, food bags, toys and automotive parts.

This polypropylene compound is known as a plastic material with superior characteristics that has high resistance to impact, heat and chemicals. In the packaging industry, C332 polypropylene bags are used to pack various products, including grains, coffee, sugar, and beans. These bags have features such as resistance to moisture and air penetration, which support the preservation of the quality of the packaged products.

Also, polypropylene compound 332C is also used in the production of automotive parts. This material is known as a suitable substitute for metals in the production of car parts due to features such as lightness, resistance to impact and corrosion, resistance to heat and chemical agents.

In general, polypropylene compound 332C as a plastic material with unique characteristics is used in various industries for various applications such as packaging, toys and automotive parts and plays an important role in improving the quality and performance of products.

Advantages and disadvantages of polypropylene compound 332C

The use of 332C polypropylene compound has many advantages, including light weight, shock and heat resistance, recyclability and easy processing. But this material also has disadvantages such as sensitivity to UV light and being weak against acids and bases.

Also, polypropylene compound 332C has suitable electrical properties for use in some electronic and electrical industries. This material can be used in the production of car parts, household appliances, toys, sports equipment, etc.

One of the advantages of this compound is the ability to produce parts with different and beautiful colors, which is very important for industries that pay attention to the beauty and appearance of parts. Also, this material is used as a substitute for traditional plastics and can reduce costs and increase production efficiency.

In general, polypropylene compound 332C is a suitable option for various industries, which, with its advantages and disadvantages, provides suitable facilities for the production of various parts.

The use of polypropylene compound 332C in the automotive industry

One of the case studies in this field is the use of C332 polypropylene compound in the production of automotive parts. Due to its characteristics such as resistance to impact and heat, this material is suitable for use in automotive parts.

Due to the unique characteristics of the 332C polypropylene compound, the use of this material in the automotive industry, especially in the production of internal and external parts of cars, has received much attention. This material is known as a suitable alternative to materials such as metals and traditional plastics and has the ability to produce light and high quality parts.

The use of 332C polypropylene compound in the production of automotive parts due to its light weight and high resistance to impact and heat leads to increased efficiency and reduced costs. This material is also recyclable, which is very important in terms of protecting the environment.

In general, the use of polypropylene compound 332C in the automotive industry can lead to the improvement of product quality and efficiency, as well as to preserve the environment and reduce production costs.

The results of tests on polypropylene compound 332C

The results of the tests showed that the C332 polypropylene compound has a long life, high resistance to heat and impact, and suitable electrical properties.

With its special compounds, this compound can show good resistance against high and low temperatures, pressure and impact. Also, its suitable electrical properties make this product very suitable for use in electronic and electrical industries.

According to the results of the tests, this compound has been considered as a suitable alternative to traditional plastic materials. Among the applications of this product, we can mention automotive, electronic, packaging and protection industries.

Due to the superior features of this compound, it is expected that its use in various industries will create more improvement and efficiency and ultimately lead to an increase in the quality of products.

Environmental effects of using 332C polypropylene compound

The use of polypropylene compound 332C in various products also has positive environmental effects because this material can be recycled and can help reduce plastic waste and environmental pollution.

Polypropylene compound 332C is a new combination of polypropylene that improves the mechanical and thermal resistance of polypropylene. Also, this compound has features such as high resistance to shock and impact, resistance to heat and solvents, as well as high recyclability.

The use of 332C polypropylene compound in the production of various products such as water bottles, trash cans, disposable tablecloths, etc. can help reduce plastic consumption and protect the environment. However, to benefit from the positive environmental effects of this substance, it is necessary to consider the process of recycling and reuse of products containing this compound.

In general, the use of polypropylene compound 332C can help improve environmental conditions and reduce pollution, and hence it is introduced as an effective solution to protect the environment.

Conclusion:

Considering the unique features, wide applications and advantages and disadvantages of polypropylene compound 332C, it can be said that this material is one of the widely used and effective polymer materials in various industries. But in general, there is a need for more studies in the field of using this compound and improving its properties.