P100N extrusion heavy polyethylene compound

Heavy polyethylene extrusion compound P100N is one of the latest polymer materials produced using extrusion technology. This material has unique properties that make it a very attractive option for various industries. In this article, we examine the characteristics of this compound, its applications in various industries, and its advantages and disadvantages. Providing quality products to the consumer has always been our priority, so in order to have a higher level of quality and service in the product, to produce with Call Phenomenon Polymer.

Characteristics of compound P100N

This polymer grade is in the market under the name CRP 100 N, which code N means with natural color and without adding carbon black. At the same time, this polymer is also known as the base of X3 heavy extrusion polyethylene, and the number 100 in it shows the modulus and resistance in the hydraulic pressure test of this polymer material.

The main features of this grade are: good resistance to environmental stress cracking (ESCR), good hydrostatic strength, high impact resistance, PE100.

These features are due to comonomerization of polyethylene base with 1-butene.

P100N extrusion heavy polyethylene compound has unique properties that distinguish it from other polymer materials. This material has high impact resistance, high strength and good flexibility, which makes it very suitable for use in various industries.

As a polymer material, this compound is resistant to various conditions such as heat, humidity and mechanical stress. Also, it has good electrical properties and can resist electric current.

Other features of this compound include resistance to flames, chemical resistance, and resistance to ultraviolet rays. These features have made it a suitable material for use in some specific industries such as pressurized and irrigation pipes and fittings.

Due to these features, P100N compound can be used as a suitable substitute for other polymer materials in various industries and guarantee the improvement of performance and product quality.

Applications of compound P100N

P100N extrusion heavy polyethylene compound is used in various industries, including pipe and sewage and geomembrane industries. This material is known as a suitable alternative to traditional polymer materials and improves the quality and efficiency of final products.

In the automotive industry, compound P100N is used as an important component in the production of internal and external parts of cars. This material has characteristics such as resistance to hydrostatic pressure and environmental cracking, which makes it suitable for use in harsh conditions and industrial environments.

P100N extrusion heavy polyethylene compound

Advantages and disadvantages of compound P100N

The use of P100N extrusion heavy polyethylene compound increases the efficiency and quality of products, but this material also has a high production cost. It should also be noted that this material is not suitable for some applications and requires accurate calculation of applications.

One of the advantages of using P100N compound is the increase in resistance to heat, impact, and pressure. This compound increases the strength and hardness of the products and also improves the electrical and mechanical properties. On the other hand, the high production cost of this compound can increase the final price of the products. It should also be noted that this compound is not suitable for some applications, for example, in some cases, its amount may be excessive and cause problems. Therefore, before using this compound, you should carefully check the requirements and specifications of the product and make the right decision.

Production methods of compound P100N

Heavy extrusion polyethylene compound P100N is produced using extrusion technology. This production method is the best method for producing this compound due to its high efficiency and the ability to adjust the properties of the material.

To produce the P100N compound, heavy polyethylene is first used as a base. After that, various additives such as absorbent materials, dyes, anti-UV materials, etc. are added to polyethylene to give it various properties such as heat resistance, strength, flexibility and color stability.

The extrusion method is the best possible option for the production of P100N compounds due to its high speed and precise control of temperature and pressure. In this method, raw materials are transferred into the main tank through suitable tanks and with the help of the hottest screws, where they are extruded under a certain pressure and temperature. Then, the output material passes through the output mold and comes out as a polymer sheet with desired properties.

Finally, the sheets obtained from this process can be used in various industries such as extrusions, pipes and fittings, etc. As one of the modern methods of compound production, extrusion is known as an efficient and optimal method.

Potentials of compound P100N for the development of industries

The use of P100N extrusion heavy polyethylene compound can help the development of various industries. This material is known as a suitable alternative to traditional polymer materials and can lead to improvement of the efficiency and quality of products.

Compound P100N has unique properties that make it attractive for use in various industries. This compound has high resistance to heat, impact and shock, making it an excellent choice for use in industrial applications. Also, this material has high chemical stability, which is used to produce products that interact with chemicals.

Another advantage of using P100N compound is its ability to be recycled and reused, which reduces plastic waste and preserves the environment. Also, this material has high deformability and formability, which makes it suitable for use in industries that require different shapes and sizes. In general, P100N compound can help the development and progress of various industries and have countless benefits.

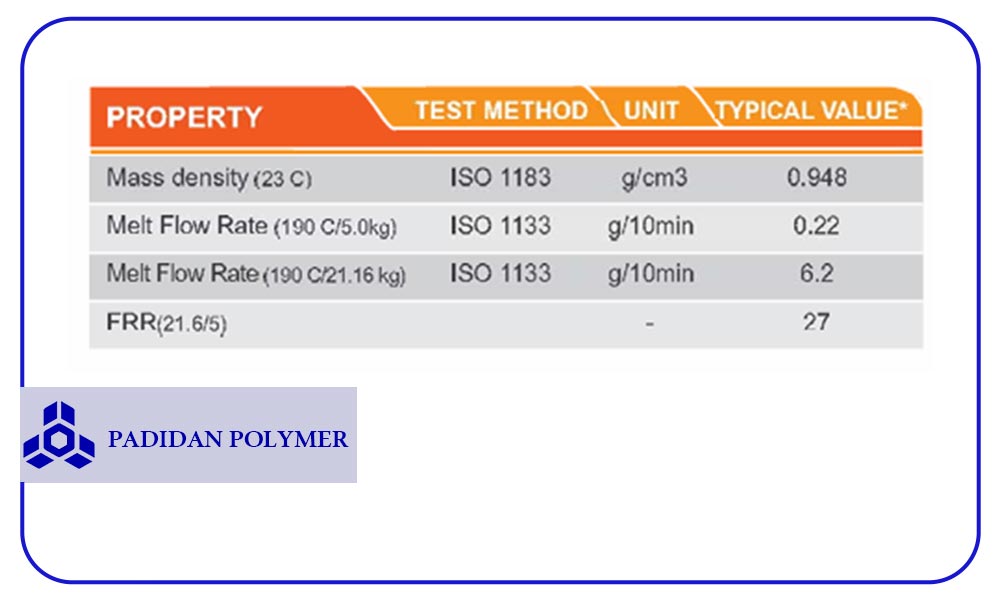

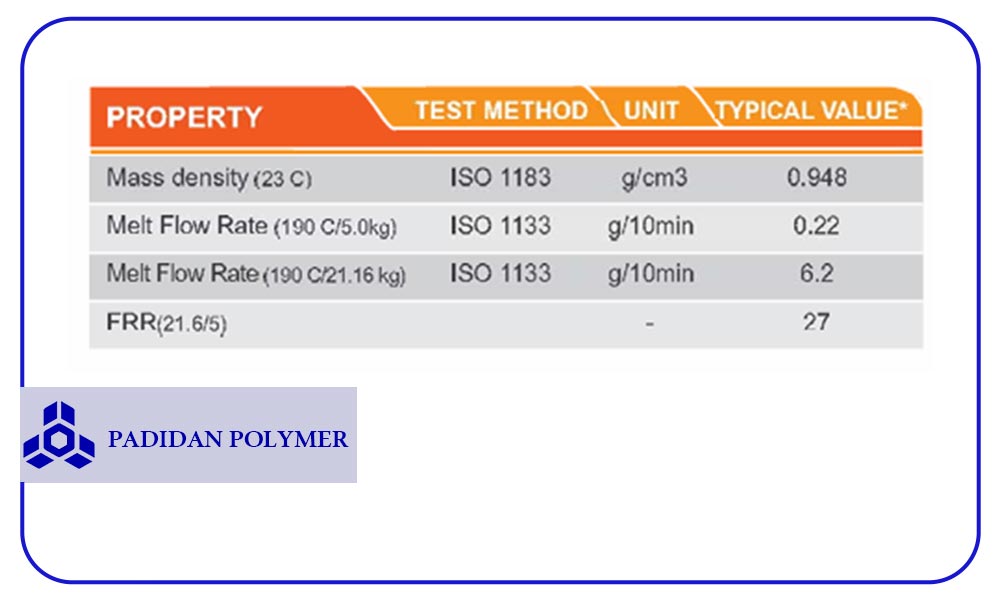

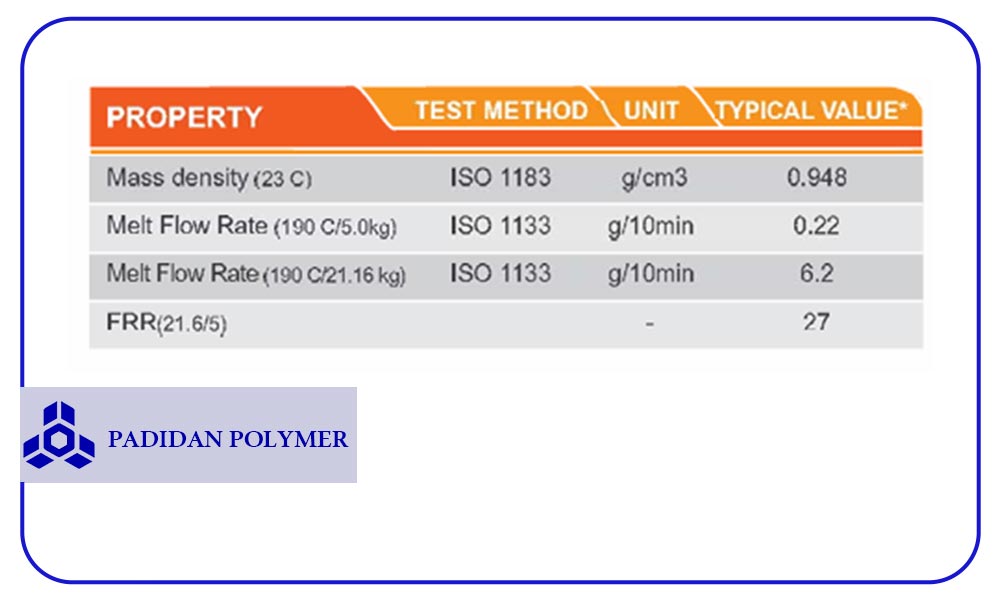

In the image below, the technical information table of this widely used grade available in Pedean Polymer’s product portfolio is presented:

P100N extrusion heavy polyethylene compound

Research and future research in the field of P100N compound

Future research and research in the field of P100N extrusion heavy polyethylene compound can help to better understand and improve the efficiency of this material. This material still has many opportunities for use in various industries and future research can help improve the properties of this material.

Future research in the field of P100N compound can help to improve the mechanical, thermal and chemical properties of this material. Among the research that can be done, it is possible to mention the improvement of heat and fire resistance, increase of strength and hardness, improvement of chemical resistance and increase of time stability. In addition, research can help reduce the cost of production and use of this material.

Also, future researches can help to improve the manufacturing methods and production processes of this compound. By using new and up-to-date technologies, it is possible to improve the quality and efficiency of this material and find new uses for it. In general, future research in this field can lead to the development of various industries and create new opportunities in global markets.

Conclusion:

Due to the unique features, wide applications and high potentials of P100N extrusion heavy polyethylene compound, it can be said that this material is a very attractive option for various industries. But for better use of this substance, more research is needed in its field.