Polyethylene compound 2420 LDPE

Polyethylene compound 2420 LDPE is one of the important types of polymers that are used in various industries due to its unique characteristics. Low-density polyethylene (LDPE) is used in the production of a variety of products, including packaging, agricultural films, and electronic components, due to its flexibility, moisture resistance, and suitable chemical properties. In this article, we will review the features, applications, production process and advantages and disadvantages of this type of polyethylene.

Buy and sell polyethylene compound 2420 LDPE

Providing quality products to the consumer has always been our priority, so to have a higher level of quality and service in the product for production, contact Pididan Polymer. In this article, the features, uses and benefits of 2420 LDPE polyethylene compound will be reviewed. . Pedean Polymer is ready to sell 2420 LDPE in Tehran and all over Iran for you dear customers.

History and development of polyethylene

Polyethylene was first produced in 1933. This polymer was quickly noticed in the plastic industry and with the development of production and processing technologies, different types of it were created. LDPE, as one of the types of polyethylene, is known as a very popular material in various industries due to its chain structure and special characteristics.

Polyethylene compound 2420 LDPE

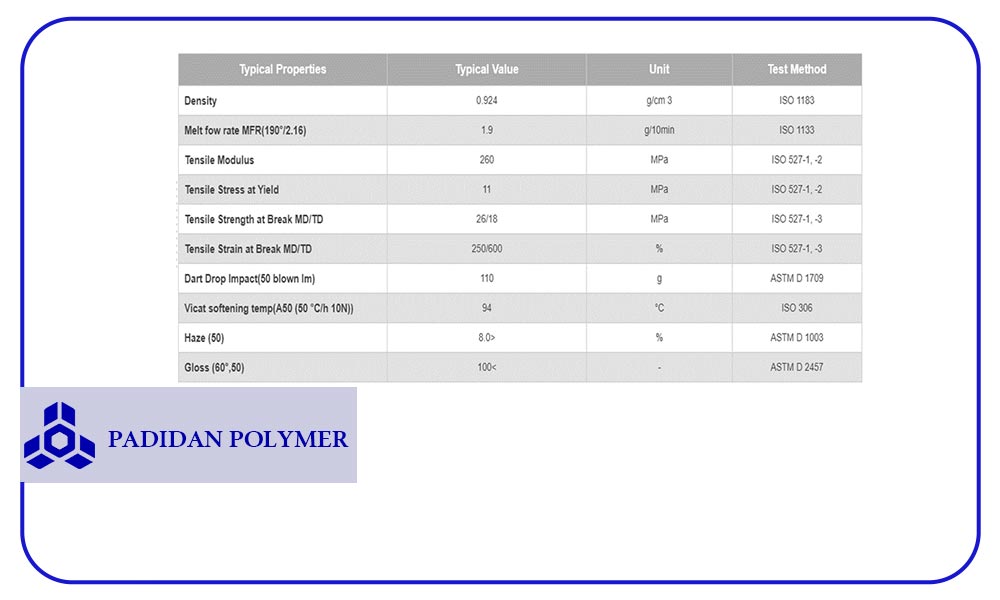

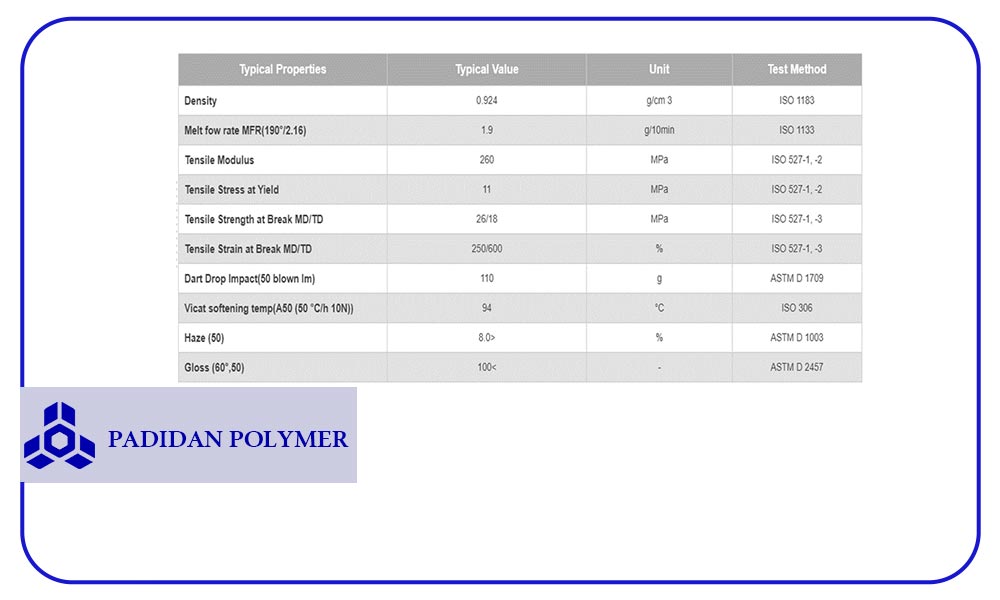

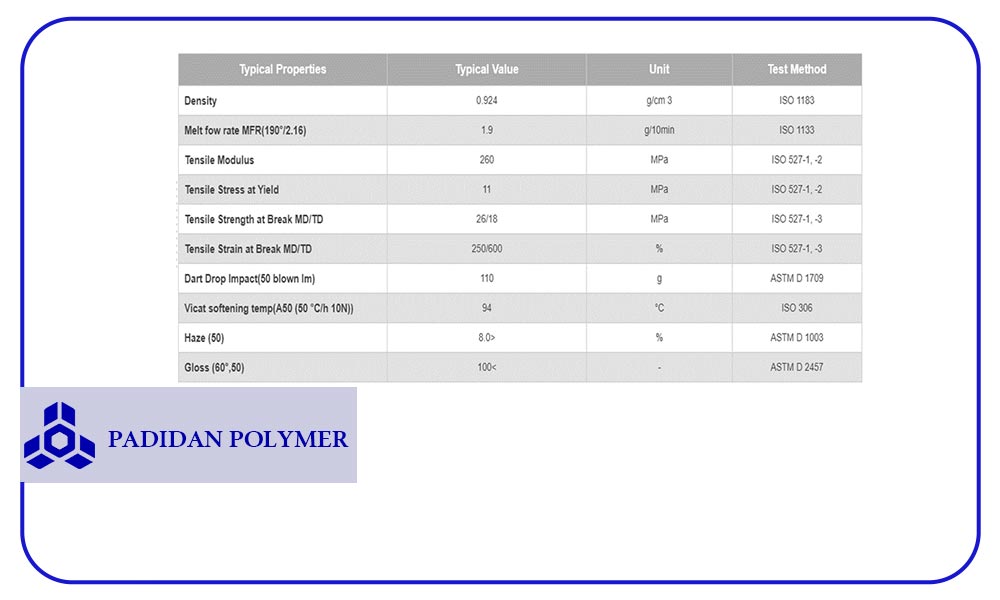

Features of polyethylene compound 2420 LDPE

Polyethylene compound 2420 LDPE has unique properties that distinguish it from other polymers. Some of these features include:

1. Flexibility: LDPE has high flexibility due to its branched chain structure, which makes it suitable for the production of products that require bending and deformation.

2. Chemical resistance: This type of polyethylene is resistant to many chemicals and solvents, which makes it ideal for industrial applications and chemical packaging.

3. Thermal stability: LDPE is stable at high temperatures and therefore can be used in thermal applications.

4. Moisture resistance: The waterproof properties of LDPE make this material used in the production of moisture-resistant packaging, especially in the food industry.

5. Easy processability: LDPE is easy to process and can be produced in various forms.

Applications of polyethylene compound 2420 LDPE

Polyethylene compound 2420 LDPE has many applications in various industries. Some of its most important uses are:

1. Food packaging: LDPE is used as a suitable material for the production of food packaging films. Due to its anti-moisture properties and resistance to pollution, this material is a suitable choice for preserving the freshness of food products.

2. Pipes and fittings: This type of polyethylene is used in the production of pipes and fittings. The high flexibility of LDPE makes these pipes easy to install and manage.

3. Agricultural films: LDPE is used as anti-UV and anti-fog films in agriculture. These films help farmers protect their crops from adverse weather conditions.

4. Electronic components: LDPE is used in the production of electrical insulation and other electronic components. This material is very useful in this industry due to its electrical insulation properties.

5. Consumer products: This type of polyethylene is used in the production of consumer products such as bags, bottles and containers.

Production process of polyethylene compound 2420 LDPE

The LDPE production process includes several main steps:

1. Polymerization: In this step, ethylene is converted into polyethylene by various methods, including polymerization under pressure and temperature. This process is usually carried out in the presence of catalysts.

2. Cooling and shaping: After polymerization, the produced polyethylene is cooled and transformed into different forms such as granules or films.

3. Quality testing: The manufactured products are subjected to quality tests to ensure compliance with industrial standards.

Polyethylene compound 2420 LDPE

Advantages and disadvantages of polyethylene compound 2420 LDPE

benefits

1. Affordable price: LDPE is generally affordable compared to other polymers, which makes it suitable for economical production.

2. Recyclability: This type of polyethylene is recyclable and can be returned to the production cycle, which helps reduce waste.

3. Diversity in production: LDPE can be transformed into various shapes and products due to its high processability.

Disadvantages

1. Less resistance to high temperatures: LDPE is less resistant to high temperatures than some other polymers and may undergo deformation in certain conditions.

2. UV stability: This type of polyethylene is not stable against UV rays and may change color and reduce properties when exposed to sunlight. Anti UV additives are used to prevent this process.

Types of grade 2420:

2420 h Amirkabir Petrochemical

2420 d Amirkabir Petrochemical

2420 f Amirkabir Petrochemical

2420 k Amirkabir Petrochemical

2420 F8 Kurdistan Petrochemical

2420 F3 Kurdistan Petrochemical

2420 E02 Kurdistan Petrochemical

conclusion

Polyethylene compound 2420 LDPE, as one of the most important polymers, has many features and applications that have made it a popular choice in various industries. From food packaging to electronic components, this type of polyethylene has been able to meet the diverse needs of industries. Despite the many advantages, the disadvantages of this type of polyethylene should also be considered, especially in applications that require resistance to high temperatures or UV rays. Due to the ability of recycling and easy processing of LDPE, it is expected that this material will remain as a sustainable and economical option in various industries in the future.

For more information, contact padidan polymer.