ABS compound W157

ABS compound W157 is one of the widely used materials in various industries. Due to its unique properties, including high mechanical strength, malleability and chemical resistance, this material is known as an ideal option for manufacturing a variety of products in the automotive, electronics, home appliance and other industries. In this article, we will review the features, applications, production process and advantages and disadvantages of ABS compound W157. Providing quality products to the consumer has always been our priority, so to have a higher level of quality and service in the product to produce with Call Polymer.

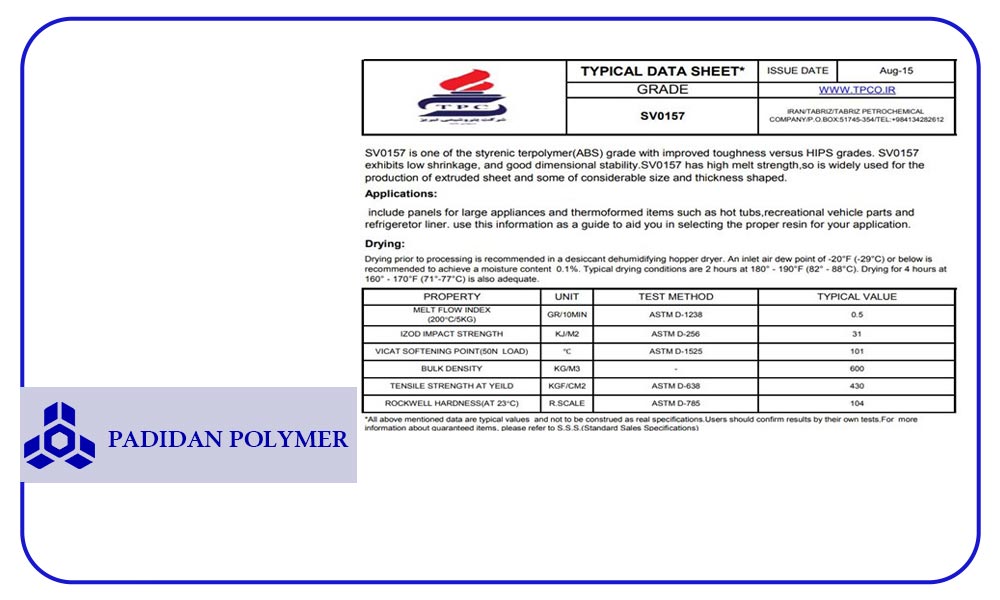

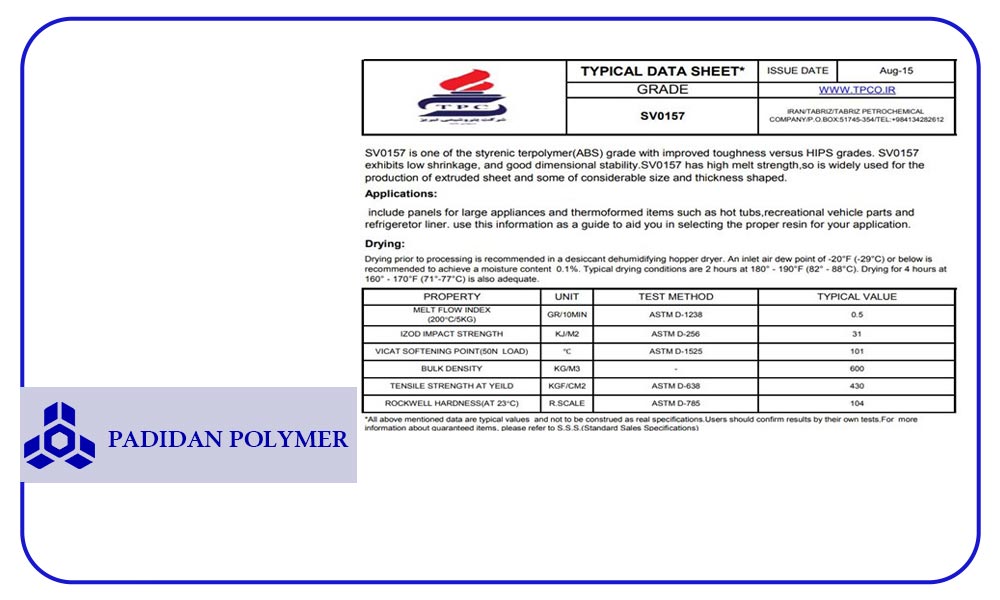

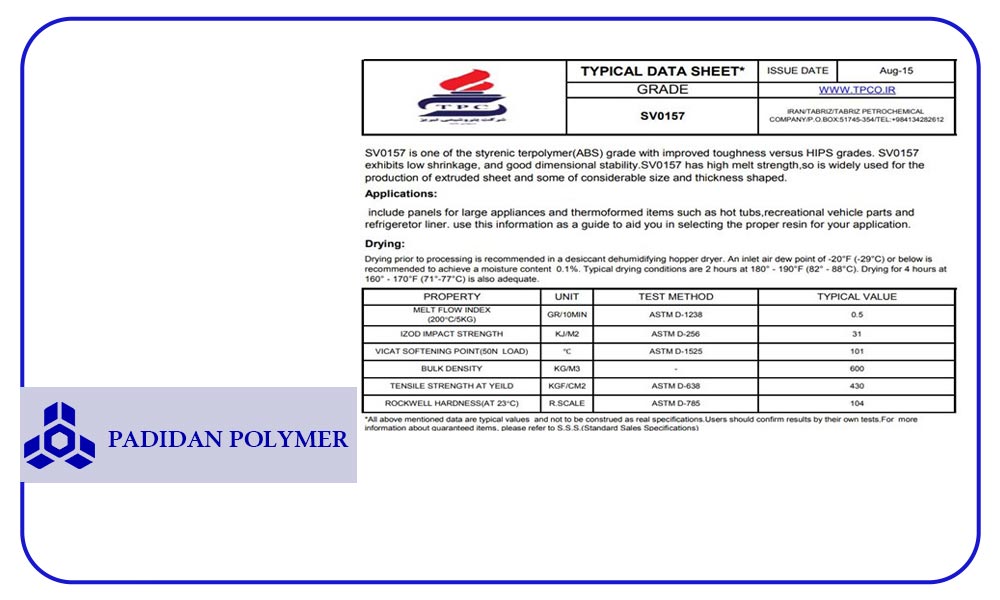

Characteristics of W157 ABS compound

1. Chemical composition and structure

ABS (acrylonitrile-butadiene-styrene) compound consists of three main monomers: acrylonitrile, butadiene and styrene. This combination gives it outstanding mechanical and chemical properties. In ABS W157, the ratio of these compounds is adjusted to provide the best performance in different conditions.

2. Strength and hardness

One of the distinctive features of ABS W157 is its high strength and hardness. This material is able to withstand pressure and mechanical stresses, and for this reason, it is widely used in industrial applications that require durable materials.

3. Formability

W157 ABS compound has high plasticity. This feature allows manufacturers to produce parts with complex shapes using various methods such as injection molding.

4. Chemical resistance

This compound also has good resistance to chemicals and corrosive environments. This property makes ABS W157 perform well in applications that are in contact with chemicals.

5. Can be painted and decorated

ABS compound W157 can be easily painted and decorated. This feature allows designers and manufacturers to produce beautiful products with different colors and patterns.

ABS compound W157

Applications of W157 ABS compound

1. Automotive industry

One of the most important applications of W157 ABS is in the automotive industry. This material is used as a suitable option for the production of car interior parts, such as dashboard, center console and door panels.

2. Electronics industries

In the electronics industry, ABS W157 is used as a coating and body for electronic devices such as televisions, computers, and smartphones. The resistance of this material against heat and impact makes it suitable for these applications.

3. Household appliances

ABS compound W157 is used in the production of household appliances such as refrigerators, dishwashers and small electrical appliances due to its beautiful appearance and technical capabilities.

4. Sports equipment

In the sports equipment industry, ABS W157 is used to produce sports equipment such as balls and training equipment. Due to its high strength and durability, this material is an excellent option for this type of products.

5. packaging

ABS compound W157 is used as a material to produce durable and beautiful packaging. These packages are usually used in pharmaceutical and food industries.

Production process of W157 ABS compound

1. Primary production process

The production of W157 ABS compound is usually done through polymerization. In this process, the raw materials of acrylonitrile, butadiene and styrene are combined under certain conditions to create ABS polymer.

2. Adding additives

After the base polymer is produced, various additives are added to it. These materials may include pigments, anti-UV materials, and other property-enhancing materials. This step allows manufacturers to create the properties they want in the final product.

3. Molding process

After preparing the compound, this material is transformed into desired shapes by various methods such as injection molding or extrusion. This process allows manufacturers to produce high quality and high precision products.

Advantages and disadvantages of W157 ABS compound

benefits

1. High strength: This compound has high mechanical strength, which makes it ideal for industrial applications.

2. Malleability: ABS W157 is easily malleable and complex parts can be produced with it.

3. Chemical resistance: This material is resistant to chemicals and corrosive environments.

4. Ability to paint: The ability to paint and decorate this material allows manufacturers to produce beautiful products.

Disadvantages

1. UV sensitivity: ABS W157 may be vulnerable to UV radiation and therefore should be used with caution in outdoor applications.

2. Limited thermal resistance: This material may undergo deformation at very high temperatures, and hence it is not suitable for high temperature applications.

3. Low degradability: ABS compound W157 is not easily decomposed and this issue can lead to environmental problems.

conclusion

ABS compound W157 is very popular as one of the widely used materials in various industries due to its technical and mechanical characteristics. From the automotive industry to electronics and home appliances, this material is used in the production of all kinds of products due to its strength, malleability and chemical resistance. Although this material has many advantages, its limitations and disadvantages should also be considered. In general, ABS W157 compound is a suitable option for the production of various industrial and consumer products due to its features and applications