ABS 10415 compound

ABS 10415 compound is one of the widely used polymer materials in various industries. This material is a combination of acrylonitrile butadiene styrene, which has attracted the attention of designers and manufacturers with its unique features. This article examines the features, uses, advantages and disadvantages of this compound and will analyze the market and its future trends.

Providing quality products to the consumer has always been our priority, so to have a higher level of quality and service in the product for production, contact Pididan Polymer.

Characteristics of ABS 10415 compound

ABS 10415 compound has special features that distinguish it from other polymer materials. These features include:

High mechanical resistance:

This compound has high tensile and impact strength, which makes it suitable for industrial applications.

Chemical resistance:

ABS 10415 is resistant to many chemicals, making it ideal for use in industrial environments.

Easy processing capability:

This compound is easily formed using different production methods such as injection and extrusion.

Thermal stability:

ABS 10415 can operate at high temperatures without changing its physical properties.

Light weight:

This material weighs less than many other materials, which reduces the weight of the final product.

Applications of ABS compound 10415

ABS 10415 compound is used in various industries due to its unique features. Some of its important uses are:

Electronics industry: This compound is used in the production of frames and bodies of electronic devices due to its high electrical and thermal resistance.

Automotive industry: ABS 10415 is used in the manufacture of internal car parts, such as dashboards and panels.

Household appliances: This compound is used in the production of household appliances such as blenders and kitchen appliances.

Medical industry: It is used in the production of medical equipment and laboratory equipment due to its hygienic and sterile properties.

Advantages and disadvantages of ABS 10415 compound

benefits

Variation of color and texture: The possibility of production in different colors and textures is one of the other advantages of this compound.

Environmentally friendly: Due to its recycling and degradability processes, this material is considered a better option for the environment than some other plastics.

Disadvantages

Low resistance to extreme heat: at very high temperatures, this compound may change shape and reduce mechanical properties.

Market analysis and future trends

The ABS 10415 compound market is currently growing. Due to the increase in demand in the automotive, electronics and home appliance industries, it is expected that this trend will continue in the coming years. In addition, due to global efforts to reduce pollution and use sustainable materials, manufacturers are moving towards improving the production and recycling methods of this compound.

conclusion

ABS 10415 compound, as a polymer material with outstanding features, has wide applications in various industries. According to its advantages and disadvantages, this compound is known as a suitable option in the production of industrial and consumer products. Considering the market trends and the increasing needs of various industries, we can expect that this compound will remain as one of the main materials in various industries in the future and will continue to improve its performance with new innovations in the field of production and recycling.

Additionally, the flexibility and ease of processing of ABS 10415 compound make it an attractive option for manufacturers. This material can be used in various processes such as injection molding and extrusion, which helps to reduce production costs and increase production speed. Also, the high resistance of this compound against impact and environmental conditions makes the products produced with it have a longer life and are more resistant to physical and chemical damage.

Considering all these factors, it can be said that ABS 10415 compound will be used not only now, but also in the future as a key material in various industries and will play a fundamental role in the direction of sustainable development and optimization of production processes. did

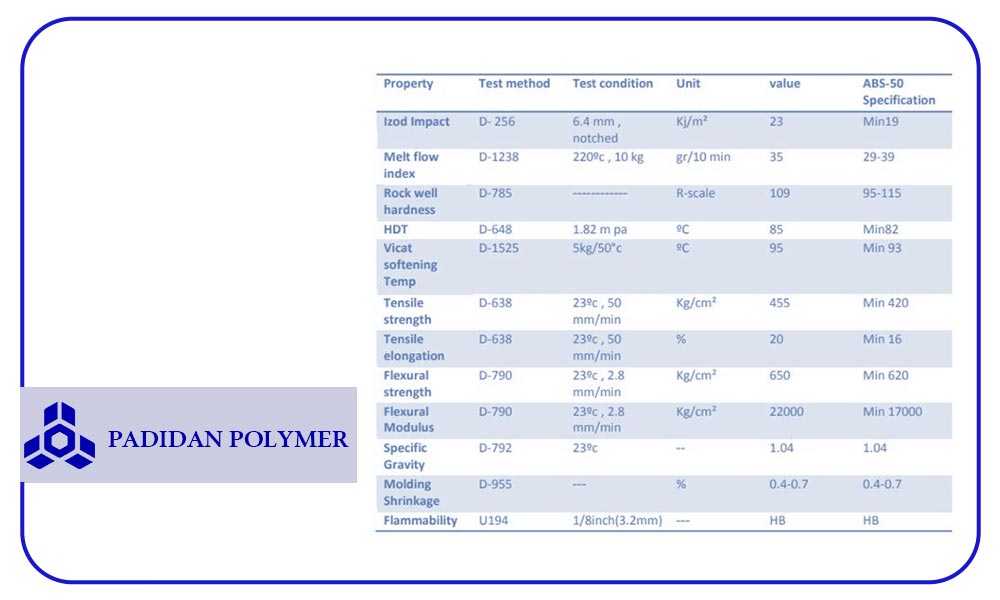

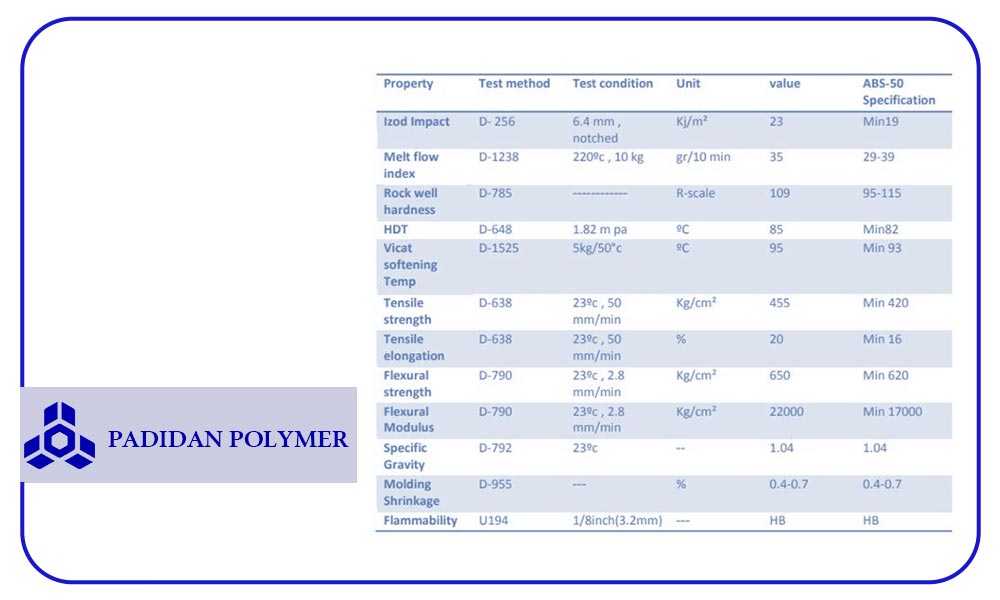

The technical table of this widely used polymer is presented for a more detailed examination of its properties.