Injectable polyethylene compound 52518

Injectable polyethylene compound 52518 is an important chemical used in various industries. This composition consists of polyethylene and various additives that give it unique properties. In this article, we examine the features, uses and production methods of injection polyethylene compound 52518. The important features of this compound include high resistance to heat and impact, proper flexibility, light weight, and resistance to various chemicals.

The production methods of this composition include combining various additives with polyethylene, precise and compact injection of materials into various molds, and then neutralization and cooling of the final product. These methods produce a product with desirable and standard properties.

Finally, injection polyethylene compound 52518 is a very important and practical material that is used in various industries and helps the development and progress of these industries. Providing quality products to the consumer has always been our priority, so for Having a higher level of quality and service in the product, contact Pedidan Polymer for production.

Characteristics of injection polyethylene compound 52518

Injectable polyethylene compound 52518 has unique features that distinguish it from other polyethylene compounds. This composition has high strength, good flexibility and excellent resistance to corrosion and heat. These features make it a widely used material in various industries.

Injectable polyethylene compound 52518 is a unique combination of polyethylene that is used in various industries. This material has high strength, which makes it suitable for use in parts that require resistance to pressure and tension. Also, it has good flexibility that allows easy processing and production of complex parts.

This compound also has excellent resistance to corrosion and heat, which makes it an excellent option for use in harsh conditions in various industries. Due to these unique features, injection polyethylene compound 52518 is one of the widely used and effective materials in various industries.

Applications of injection polyethylene compound 52518

Injectable polyethylene compound 52518 is used in various industries such as packaging, automotive, electronics and medicine. Among the applications of this combination, we can mention the production of car parts, medical tools and packaging materials. Due to its unique features, this compound is very important for sensitive industries that require high quality materials.

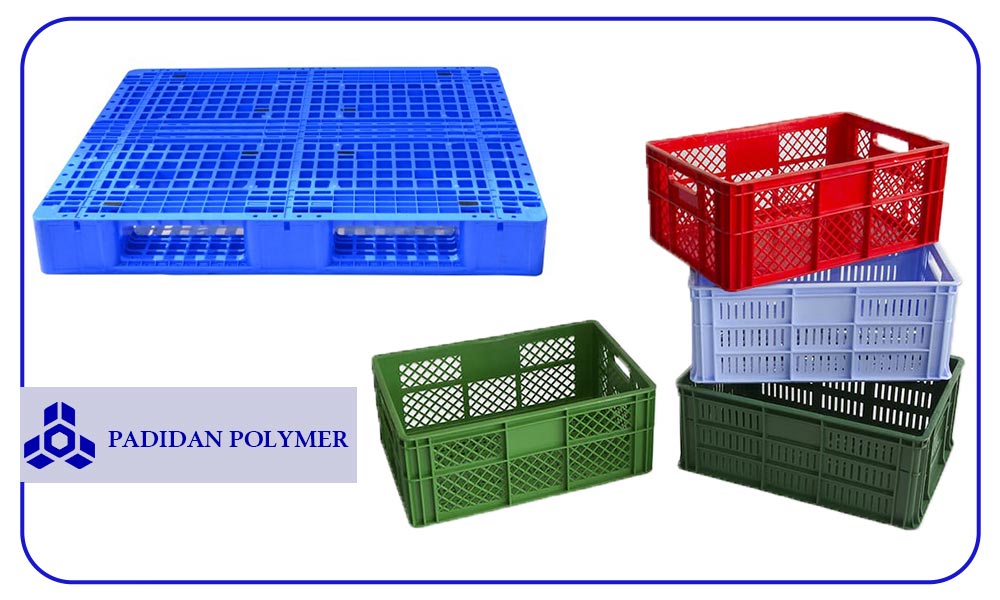

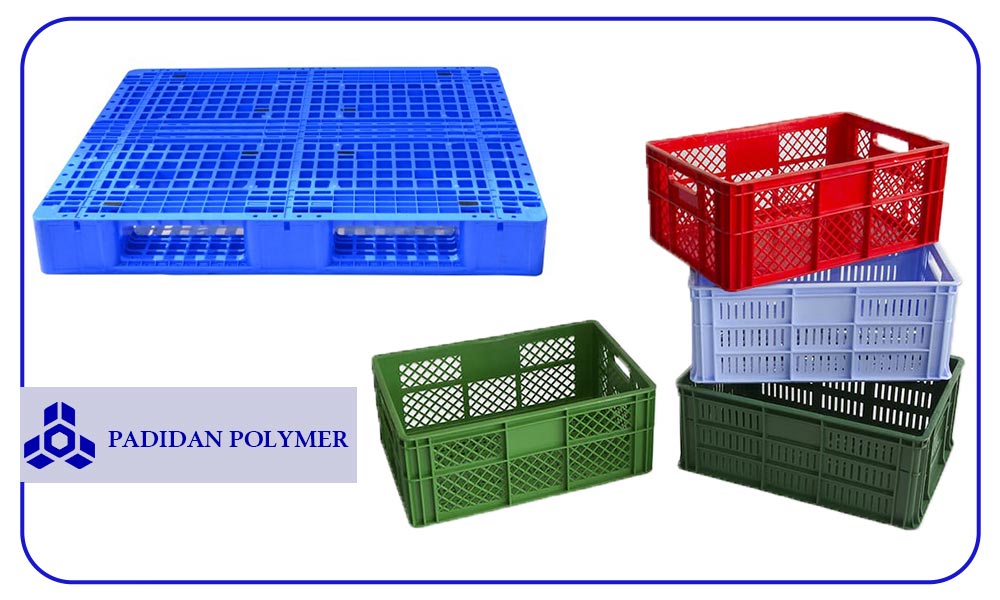

Injectable polyethylene compound 52518 is one of the materials used in some important industries. This compound is used in kitchen appliances and toys or plastic pallets.

Production methods of injection polyethylene compound 52518

Production of injection polyethylene compound 52518 is done in several different ways. One of the usual methods of producing this compound is adding special additives to polyethylene in the extrusion process. This method is one of the most popular methods for producing injection polyethylene compound 52518 due to its simplicity and efficiency.

The methods of producing injection polyethylene compound 52518 are varied, but one of the common and popular methods for producing this compound is adding special additives to polyethylene in the extrusion process. In this method, additives such as antioxidants, UV protectants are added to the polyethylene to achieve the properties required for the 52518 injection polyethylene compound. Due to its simplicity and efficiency, this method has the ability to mass produce with high quality. Also, this method can be deployed automatically without the need for human access, which improves the performance and efficiency of the production process.

Experiments and quality tests of injection polyethylene compound 52518

To ensure the quality and better performance of injection polyethylene compound 52518, various experiments and tests are performed. These tests include mechanical, thermal and chemical tests, whose purpose is to investigate and evaluate the physical and chemical properties of this compound.

To ensure the quality and better performance of injection polyethylene compound 52518, various experiments and tests are performed. These tests include mechanical, thermal and chemical tests, whose purpose is to investigate and evaluate the physical and chemical properties of this compound. Mechanical tests include the analysis of fracture resistance, flexibility and wear of materials. Thermal tests are performed to check the tolerance of materials at different temperatures and thermal changes. Also, chemical tests are conducted to check the chemical composition, stability and chemical properties of the compound. These tests ensure the quality and better performance of this product and provide manufacturers and consumers with useful information related to this product.

Challenges and solutions in the production of injection polyethylene compound 52518

The production of injection polyethylene compound 52518 is faced with various challenges, such as choosing the right additives, setting the right temperature and pressure, and quality control. To solve these challenges, it is necessary for manufacturers to use new technologies and advanced methods.

The production of injection polyethylene compound 52518 is a complex process that faces various challenges. Choosing the right additives to improve the mechanical, thermal and physical properties of materials is one of the main challenges in the production of this product. Also, proper temperature and pressure adjustment in the production process is very important. In addition, quality control and ensuring the necessary standards are among other challenges in this industry. To solve these challenges, manufacturers must use new technologies and advanced methods to improve the production process and product quality.

Suggestions for improving the quality of injection polyethylene compound 52518

To improve the quality and better performance of injection polyethylene compound 52518, it is possible to improve production methods, use high quality materials and conduct regular quality tests and experiments. These measures can improve the performance and usability of this combination.

To improve production methods, upgrading of production equipment and processes can be used. These measures can guarantee the improvement of the quality and accuracy of polyethylene compound production. Also, the use of high quality materials and international standards in the selection of raw materials can significantly improve the final quality of the product.

On the other hand, conducting regular quality tests can help identify problems and defects in the product and prevent low-quality products. These tests can include physical, chemical and mechanical tests that help to improve the quality and performance of the product. In general, doing these suggestions and actions can significantly improve the quality and performance of injection polyethylene compound 52518 and increase customer satisfaction. to give

Conclusion:

Injectable polyethylene compound 52518 is a chemical substance with unique properties that is used in various industries. This compound has superior physical and chemical properties that have made it a highly sought-after material in various industries. By conducting regular quality tests and tests and using advanced manufacturing methods, the quality and performance of this compound can be improved.